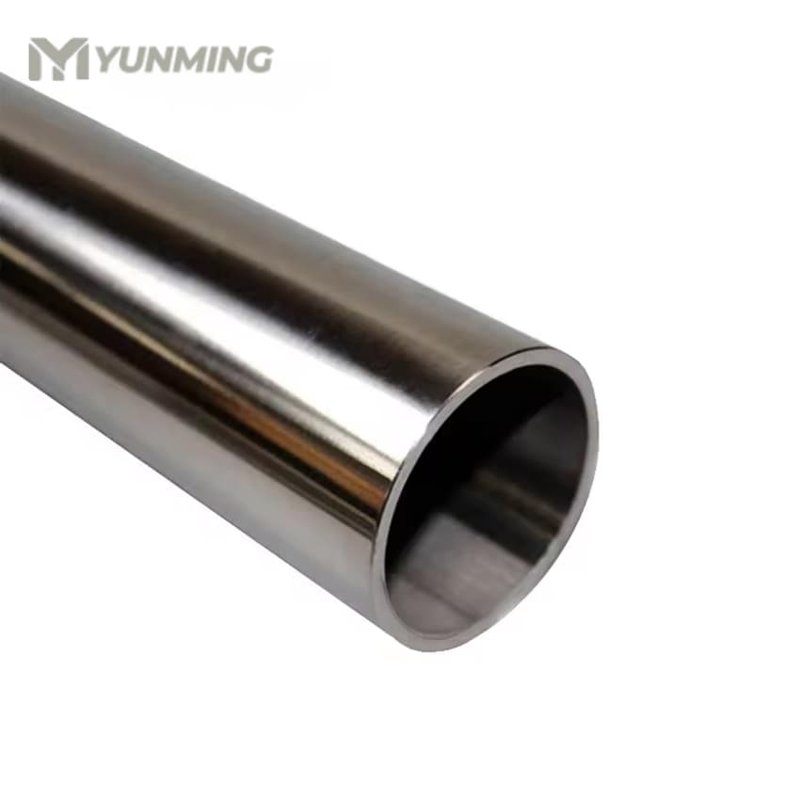

Stainless Steel Precision Tube

Yunming Metal’s Stainless Steel Precision Tubes offer tight tolerances, smooth finishes, and excellent performance for medical, automation, and high-precision industrial applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Yunming Metal’s Stainless Steel Precision Tubes are manufactured with extremely tight tolerances, smooth surfaces, and consistent mechanical properties, making them ideal for high-precision industrial applications. These tubes are produced by cold drawing or cold rolling processes to achieve superior dimensional accuracy and surface finish.

They are widely used in industries requiring high cleanliness, exact inner and outer diameters, and minimal deviation, such as medical, instrumentation, electronics, and automation.

Application Areas

-

Medical devices and surgical instruments

-

Precision machinery and equipment manufacturing

-

Automotive fuel injection systems and brake lines

-

Hydraulic and pneumatic control systems

-

Semiconductor and instrumentation tubing

-

Aerospace and laboratory applications

Product Features

-

Tight dimensional tolerances and concentricity

-

Ultra-smooth inner and outer surfaces

-

Excellent corrosion and pressure resistance

-

Superior cleanliness for sensitive applications

-

Good weldability and cold workability

-

Available in seamless and welded options

Technical Specifications

| Item | Description |

|---|---|

| Material Grades | 304, 304L, 316, 316L, 321, 310S, 904L, duplex 2205, etc. |

| Outer Diameter Range | 0.3mm – 50mm (approx. 1/64″ – 2″) |

| Wall Thickness Range | 0.05mm – 3.0mm (approx. 3/2000″ – 1/8″) |

| Length | Fixed length or coil tubing, customized on request |

| Surface Finish | Bright Annealed, Polished, Pickled, etc. |

| Standards | ASTM A269, ASTM A632, EN 10216-5, DIN 2462, etc. |

Manufacturing Process

Our stainless steel precision tubes are manufactured through an advanced cold drawing process, followed by precision annealing and finishing steps:

-

Selection of high-purity stainless steel raw materials

-

Cold drawing or cold rolling to achieve required dimensions

-

Bright annealing in a controlled atmosphere

-

Straightening and length adjustment

-

Surface treatment: pickling, polishing, or passivation

-

100% dimensional and surface inspection

-

Optional eddy current or ultrasonic testing for critical applications

Frequently Asked Questions (FAQ)

Q1: What makes precision tubes different from regular stainless steel tubes?

A1: Precision tubes have tighter dimensional tolerances, better surface finishes, and are often used in applications requiring exact size control and cleanliness.

Q2: Do you offer seamless or welded precision tubes?

A2: Yes, we supply both seamless and welded precision tubes based on customer needs and application requirements.

Q3: Can I request ultra-thin wall precision tubes?

A3: Absolutely. We offer precision tubes with wall thickness as low as 0.05mm, suitable for micro-scale or sensitive fluid applications.

Q4: What quality inspections do you perform?

A4: Our tubes undergo dimensional inspection, surface quality check, and optional NDT methods like eddy current or ultrasonic testing.

Q5: Are these tubes suitable for high-pressure fluid systems?

A5: Yes, especially the seamless precision tubes are suitable for high-pressure, high-purity, and leak-sensitive systems.

Still Have Questions?

For custom specifications or further consultation, contact our technical team. Yunming Metal offers tailored stainless steel precision tube solutions for your specific project requirements.