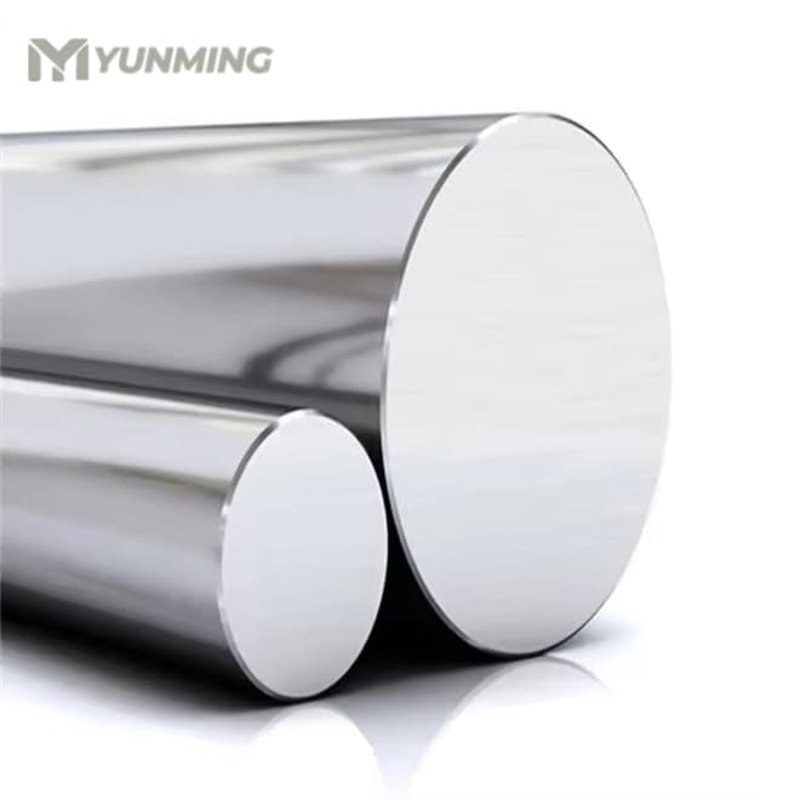

Stainless Steel Round Bar

Yunming Metal supplies stainless steel round bars in a wide range of grades and sizes. Available in hot rolled, cold drawn, and centerless ground finishes for machining, construction, and structural applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Our stainless steel round bars are precision-manufactured for superior strength, corrosion resistance, and dimensional accuracy. Widely used in industrial and structural applications, these bars are suitable for machining, construction, shafts, and fasteners in both corrosive and high-stress environments.

Application Areas

-

Machining & Tooling: Shafts, gears, and machine components.

-

Construction & Infrastructure: Structural reinforcements and support elements.

-

Petrochemical Industry: Equipment exposed to corrosive media.

-

Automotive Industry: Drive shafts, axle components, and fasteners.

-

Marine & Offshore: Corrosion-resistant parts for marine environments.

-

Medical & Food Equipment: Hygienic and oxidation-resistant components.

Product Features

-

Wide range of material grades including duplex and high-performance alloys

-

Excellent resistance to corrosion, heat, and mechanical stress

-

Precision tolerance and consistent surface finish

-

Available in hot rolled, cold drawn, or centerless ground finish

-

Customized cutting and machining options

Technical Specifications

| Item | Description |

|---|---|

| Material Grades | 304, 304L, 316, 316L, 321, 310S, 317L, 904L, 410, 416, 420, 430, 431, duplex 2205, 2507, etc. |

| Diameter Range | 3mm – 500mm (approx. 1/8″ – 19 11/16″) |

| Length | 1000mm – 12000mm (approx. 3′ 3″ – 39′ 4″) or customized |

| Tolerances | H9 – H11 (standard) or as specified |

| Surface Finish | Hot rolled, cold drawn, centerless ground, polished, or peeled |

| Manufacturing Standards | ASTM A276, ASTM A479, EN 10088, JIS G4303, DIN 17400, etc. |

Manufacturing Process

Stainless steel billets are hot rolled or cold drawn into round bars, followed by heat treatment and surface finishing processes such as peeling, polishing, or grinding. Precision machining ensures consistent tolerances and defect-free surfaces. Every batch undergoes dimensional inspection, ultrasonic testing, and chemical analysis to meet international standards.

FAQ

Q: What material grades can you supply?

A: We offer a wide range of stainless steel grades including 304, 316L, 321, 310S, 317L, 904L, duplex 2205, 2507, and other custom options upon request.

Q: What are the available surface finishes?

A: Surface options include hot rolled, cold drawn, ground, polished, and peeled finishes.

Q: Can you provide cut-to-length bars?

A: Yes, we offer customized cutting services based on client specifications.

Q: Are your round bars suitable for machining?

A: Yes, our cold drawn and centerless ground bars are ideal for precision machining.

Q: Do you provide material test certificates?

A: Yes, we provide MTCs in accordance with EN 10204 3.1 or 3.2 upon request.