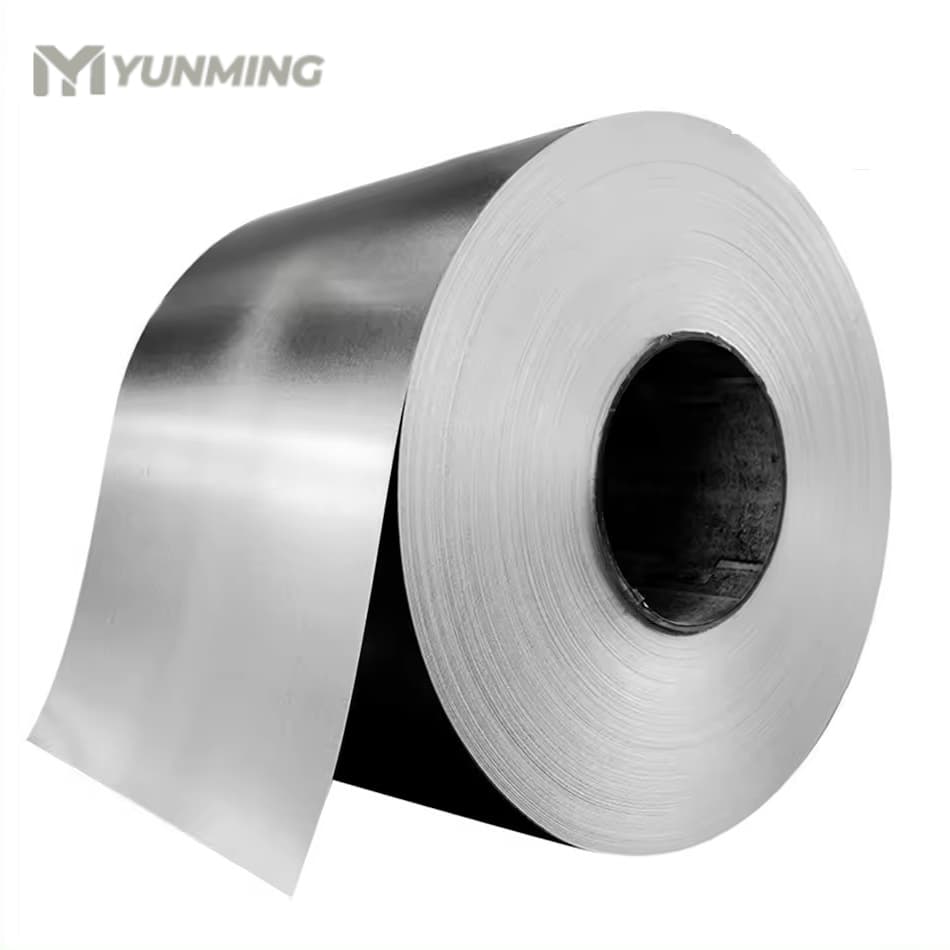

Cold Rolled Stainless Steel Coil

Yunming Metal supplies cold rolled stainless steel coil in grades like 304, 316L, and 430, offering precision thickness, excellent finish, and superior corrosion resistance for appliances, construction, and industrial applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Cold rolled stainless steel coil is processed through a cold reduction mill and then annealed and pickled to achieve precise thickness, excellent surface finish, and improved mechanical properties. It is widely used in industries where high dimensional accuracy, smoothness, and corrosion resistance are required.

Application Areas

-

Kitchen equipment and appliances

-

Automotive exhaust systems and trim

-

Precision components and electronics

-

Construction and building materials

-

Chemical processing and storage tanks

-

Heat exchangers and pressure vessels

Product Features

-

Smooth surface and excellent flatness

-

Precise thickness and tight tolerances

-

High strength with good formability

-

Excellent corrosion and oxidation resistance

-

Available in various surface finishes including BA, 2B, No.4, and 8K

Technical Specifications

| Specification | Range |

|---|---|

| Material Grades | 304, 304L, 309S, 310, 310S, 316, 316L, 316Ti, 321, 430, 410, 420, 2205, 904L |

| Standard Thickness | 0.1 mm – 8 mm (approx. ¹⁄₂₅₄″ – ⁵⁄₁₆″), customizable |

| Standard Width | 1000 mm – 1500 mm (approx. 39″ – 59″), other widths up to 2000 mm on request |

| Coil ID / OD | ID: 508 mm or 610 mm (approx. 20″ or 24″), OD: up to 2000 mm (≈ 79″) |

| Finish Options | 2B, BA, No.4, HL, 8K, brushed, mirror, and matte finishes |

| Standards | ASTM, AISI, JIS, EN, DIN, GB, SUS |

| Processing Services | Slitting, shearing, cutting, decoiling, punching, surface treatment |

Manufacturing Process

Cold rolled coils are manufactured by reducing hot rolled coils at room temperature through a series of rolling mills. The process enhances dimensional precision and surface smoothness. The coils are then annealed, pickled, and surface treated to meet various industrial standards. Final processing may include slitting, trimming, and edge conditioning.

FAQ

Q: What is the difference between cold rolled and hot rolled stainless steel coils?

A: Cold rolled coils offer better surface finish, tighter dimensional tolerances, and improved mechanical properties compared to hot rolled coils.

Q: Can I request specific coil widths and inner diameters?

A: Yes, we offer customized coil width, thickness, and ID/OD based on your processing requirements.

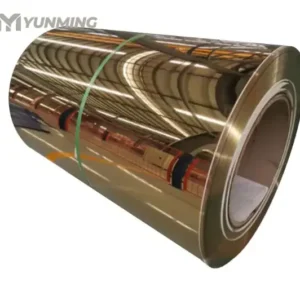

Q: Which surface finish is suitable for decorative applications?

A: BA and 8K mirror finishes are ideal for decorative and reflective applications.

Q: Is cold rolled stainless steel suitable for deep drawing or stamping?

A: Yes, grades like 304 and 316L in annealed condition are excellent for forming and deep drawing.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom cold rolled stainless steel coil requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.