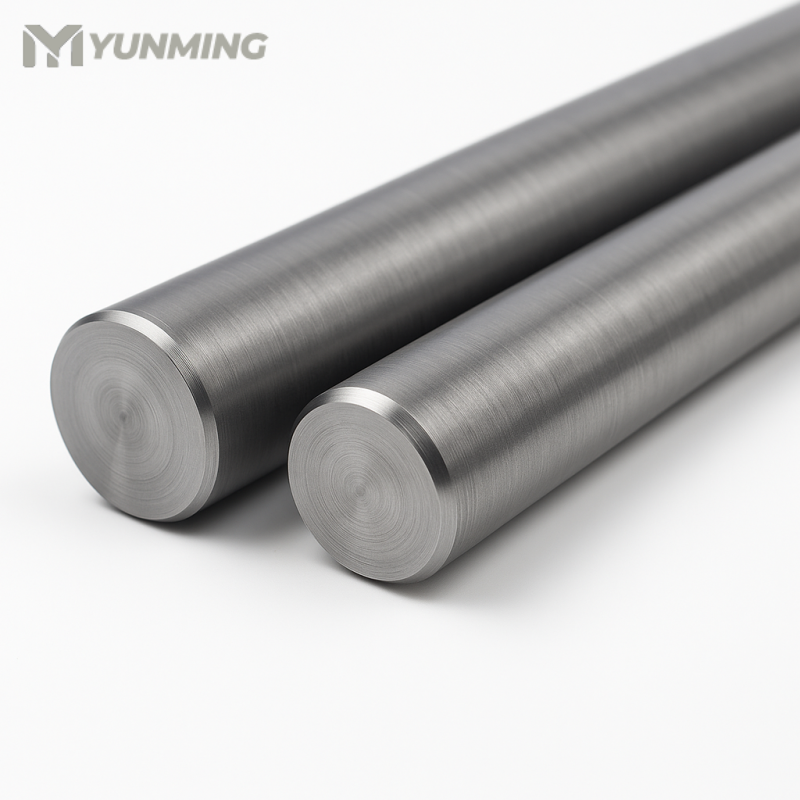

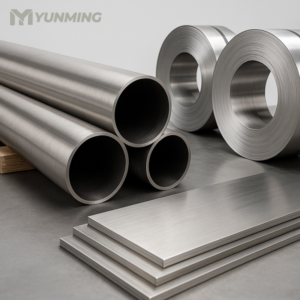

17-4PH Stainless Steel

Yunming Metal supplies precipitation hardening stainless steel including 17-4PH and 15-5PH, known for exceptional strength and corrosion resistance. Ideal for aerospace, marine, and industrial use.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

17-4PH stainless steel (UNS S17400) is a martensitic precipitation hardening stainless steel known for its exceptional combination of high strength, good corrosion resistance, and excellent mechanical properties at temperatures up to 600°F (316°C). It offers a versatile solution for industries requiring structural integrity, precision, and durability under demanding conditions.

Application Areas

-

Aerospace and aircraft components

-

Nuclear reactor parts

-

Chemical processing equipment

-

Valves, flanges, and fittings

-

Marine shafts and pump parts

-

Oil & gas field equipment

Product Features

-

High tensile and yield strength after aging

-

Excellent corrosion resistance in many environments

-

Good toughness in both longitudinal and transverse directions

-

Easily weldable and machinable

-

Heat treatable to multiple hardness conditions (H900–H1150)

Technical Specifications

| Condition | Diameter / Thickness | Width (mm / in) | Length (mm / in) | Hardness |

|---|---|---|---|---|

| Annealed | 8–300 mm / ⁵⁄₁₆″–11 ⁷⁄₈″ | up to 2000 mm / 78 ³⁄₄″ | up to 6000 mm / 236 ¹⁄₄″ | ≤ 363 HB |

| H900 | 8–250 mm / ⁵⁄₁₆″–9 ⁷⁸″ | up to 1500 mm / 59″ | up to 6000 mm / 236 ¹⁄₄″ | 44–47 HRC |

| H1025 | 8–250 mm / ⁵⁄₁₆″–9 ⁷⁸″ | up to 1500 mm / 59″ | up to 6000 mm / 236 ¹⁄₄″ | 35–40 HRC |

Manufacturing Process

-

Vacuum induction melting (VIM) or ESR

-

Hot rolled or forged to desired shape

-

Solution treated and annealed

-

Precision machining or cutting

-

Precipitation hardening (H900, H1025, etc.)

-

Final inspection, certification, and packaging

FAQ

Q1: What is the main benefit of 17-4PH stainless steel?

A: It delivers high strength and corrosion resistance with the flexibility of heat treatment for specific hardness needs.

Q2: Can 17-4PH be welded?

A: Yes, standard welding methods can be used, with post-weld aging to restore mechanical properties.

Q3: What is the aging process for 17-4PH?

A: It involves heating the material to specific temperatures (e.g., 900°F for H900) to achieve desired hardness.

Q4: Is 17-4PH suitable for marine environments?

A: Yes, it has moderate-to-good corrosion resistance in saltwater and marine conditions, especially in aged states.

Q5: What is the difference between 17-4PH and 304 stainless steel?

A: 17-4PH offers far greater strength and hardness, while 304 is more formable and corrosion-resistant in non-critical environments.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom 17-4PH stainless steel requirements.

Our technical support team is ready to assist with specifications, certifications, and delivery.