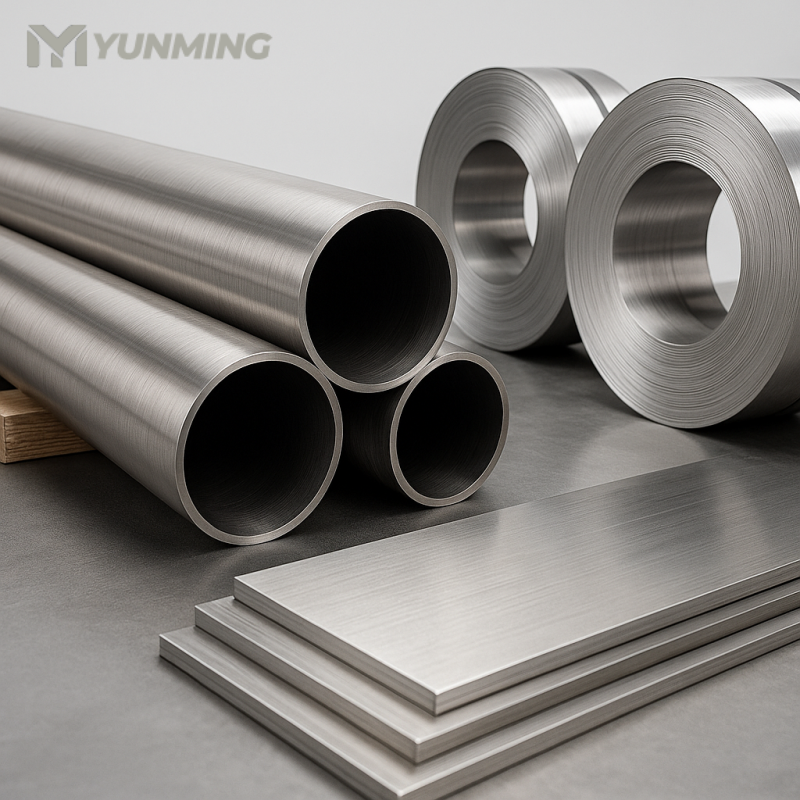

904L Stainless Steel

Yunming Metal offers 904L stainless steel in pipe, plate, and coil forms, engineered for high-performance corrosion resistance in chemical, marine, and industrial applications. Certified to ASTM standards and available for global delivery with full documentation.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

904L stainless steel is a low-carbon, high-alloy austenitic stainless steel with excellent corrosion resistance in a wide range of aggressive environments. Known for its exceptional performance in sulfuric acid, phosphoric acid, and chloride-rich conditions, 904L is commonly used in chemical processing, petrochemical, marine, and pharmaceutical industries. Its superior resistance to pitting, crevice corrosion, and stress corrosion cracking makes it ideal for critical applications.

Application Areas

- Chemical and petrochemical processing equipment

- Pulp and paper industry machinery

- Marine and offshore structures

- Heat exchangers and condensers

- Air pollution control systems

- Pharmaceutical and food processing equipment

Product Features

- Excellent corrosion resistance to sulfuric, phosphoric, and acetic acids

- Low carbon content minimizes risk of intergranular corrosion

- High resistance to pitting and crevice corrosion

- Maintains strength and toughness at elevated temperatures

- Good weldability and formability

Technical Specifications

| Product Form | Thickness / Diameter | Width / Length | Standard |

|---|---|---|---|

| Plate | 3.0 mm – 60 mm | Up to 2000 mm / Customizable | ASTM B625 |

| Pipe | Φ10 mm – Φ650 mm | SCH10 to SCH160 / Custom | ASTM B677/B673 |

| Coil | 0.3 mm – 6.0 mm | 600 mm – 1500 mm | ASTM A240 |

Other dimensions and tolerances available upon request.

Manufacturing Process

The 904L stainless steel is manufactured through a series of precision-controlled steps including melting, hot/cold rolling, annealing, pickling, and final finishing. All materials undergo rigorous quality checks to ensure compliance with ASTM, EN, and customer specifications.

View Detailed Product Pages

Frequently Asked Questions (FAQ)

1. What is the difference between 904L and 316L stainless steel?

904L offers superior corrosion resistance, especially in aggressive environments involving acids and chlorides, compared to 316L.

2. Can 904L be welded easily?

Yes. 904L is weldable using standard welding methods, though special filler materials are recommended for optimal corrosion resistance.

3. Is 904L suitable for seawater applications?

Yes. 904L has excellent resistance to chloride-induced corrosion and is used in marine and offshore environments.

4. What certifications are available for 904L materials?

Typical certifications include EN 10204 3.1 / 3.2, ASTM, and customized testing upon request.

5. What is the typical lead time for 904L products?

Lead time varies depending on dimensions and quantity, generally 7–21 days for common sizes.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom 904L stainless steel requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.