15-5PH Stainless Steel

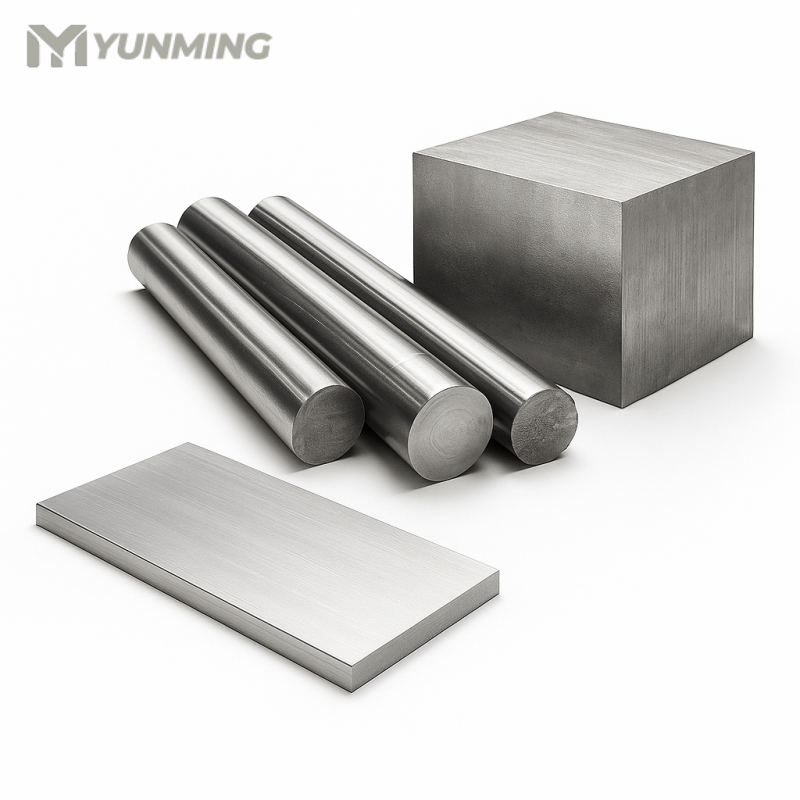

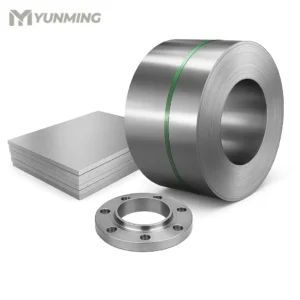

Yunming Metal supplies 15-5PH stainless steel bar, plate, and forged shapes for aerospace, marine, and nuclear applications. Known for its superior strength, corrosion resistance, and excellent toughness in all directions, including large cross-sections.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

15-5PH stainless steel (UNS S15500) is a precipitation hardening martensitic stainless steel with excellent mechanical strength, toughness, and corrosion resistance. It was developed as an improvement over 17-4PH, offering better transverse properties, especially in bar and forged shapes. Ideal for demanding aerospace and nuclear applications, it maintains good weldability and high strength even in large sections.

Application Areas

-

Aerospace structural and engine components

-

Nuclear reactor parts

-

High-performance shafts and rotors

-

Marine propulsion and fasteners

-

Valve components, flanges, and pump housings

-

Petrochemical processing equipment

Product Features

-

Improved toughness vs. 17-4PH, especially in larger cross-sections

-

High yield and tensile strength after aging

-

Excellent corrosion resistance in various environments

-

Readily machinable and weldable

-

Available in multiple aging tempers (H900–H1150)

-

Good dimensional stability during heat treatment

Technical Specifications

| Condition | Diameter / Thickness | Width (mm / in) | Length (mm / in) | Hardness |

|---|---|---|---|---|

| Annealed | 8–300 mm / ⁵⁄₁₆″–11 ⁷⁄₈″ | up to 2000 mm / 78 ³⁄₄″ | up to 6000 mm / 236 ¹⁄₄″ | ≤ 341 HB |

| H1025 | 8–250 mm / ⁵⁄₁₆″–9 ⁷⁸″ | up to 1800 mm / 70 ⁷⁄₈″ | up to 6000 mm / 236 ¹⁄₄″ | 32–38 HRC |

| H1100 | 8–250 mm / ⁵⁄₁₆″–9 ⁷⁸″ | up to 1800 mm / 70 ⁷⁄₈″ | up to 6000 mm / 236 ¹⁄₄″ | 28–34 HRC |

Manufacturing Process

-

Vacuum or ESR melting

-

Hot rolling or forging

-

Solution annealing

-

Aging heat treatment (H900–H1150)

-

Straightening, machining, and polishing

-

Final inspection and certification

FAQ

Q1: What is the main difference between 15-5PH and 17-4PH?

A: 15-5PH offers better transverse toughness and improved ductility, especially in thicker sections or forged parts.

Q2: Is 15-5PH suitable for welding?

A: Yes, it has good weldability and can be heat-treated after welding to regain full strength.

Q3: What are common aging conditions for 15-5PH?

A: H900, H1025, H1100, and H1150 are widely used, depending on the strength and ductility required.

Q4: What product forms are available?

A: 15-5PH is available in round bar, forged blocks, plates, and machined components.

Q5: Can 15-5PH be used in seawater environments?

A: Yes, its corrosion resistance is suitable for marine hardware and offshore structures, especially after aging.

Still Have Questions?

Feel free to contact us for more details or to discuss your 15-5PH stainless steel application.

Our technical team is ready to assist with sizing, certifications, and export logistics.