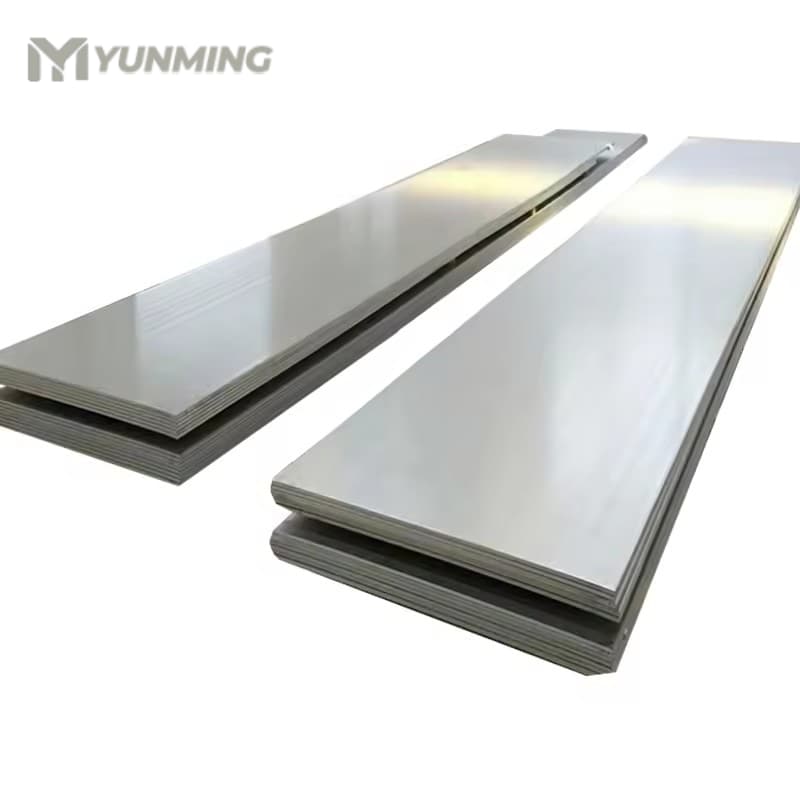

Cold Rolled Stainless Steel Sheet & Plate

Yunming Metal offers cold rolled stainless steel sheet and plate with superior surface quality, accurate thickness control, and excellent corrosion resistance. Available in a wide range of sizes, finishes, and steel grades to meet demanding industrial applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Cold rolled stainless steel sheet and plate are precision-engineered materials with excellent surface finish, tight thickness tolerance, and improved mechanical properties. They are processed below recrystallization temperature to achieve enhanced strength and surface quality. These materials are widely used in industries that demand corrosion resistance, dimensional accuracy, and a clean, smooth appearance.

Application Areas

-

Automotive Industry: Used for structural parts, exhaust systems, and decorative trims.

-

Appliance Manufacturing: Applied in refrigerators, washing machines, and kitchen equipment.

-

Architecture: Ideal for elevator panels, wall cladding, and interior decorative components.

-

Medical & Cleanroom Equipment: Required for hygienic, corrosion-resistant surfaces.

-

Precision Fabrication: Suitable for laser cutting, bending, and high-spec components.

Product Features

-

Superior Surface Finish: Bright, clean appearance suitable for visible and hygienic applications.

-

Tight Tolerance Control: Consistent thickness ensures reliability during fabrication.

-

Enhanced Strength: Cold rolling increases hardness and yield strength.

-

Excellent Corrosion Resistance: Performs well in both mild and harsh environments.

-

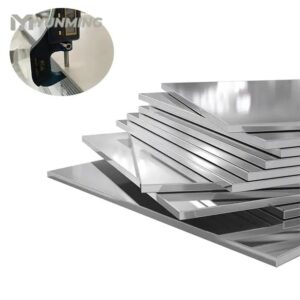

Formability: Easily cut, bent, or stamped for various industrial requirements.

Technical Specifications

| Specification | Range |

|---|---|

| Length | 100 mm – 12000 mm (4″ – 472″) |

| Width | 3 mm – 2500 mm (1/8″ – 98″) |

| Thickness | 0.03 mm – 300 mm (1/32″ – 12″) |

| Steel Grades | 304, 304L, 316, 316L, 321, 430, 2205, 2507, 904L and others |

| Surface Finishes | 2B, BA, HL, No.4, 6K, 8K, Mirror, Etched, Embossed |

| Standards | ASTM, JIS, EN, DIN, GB, SUS |

| Processing Methods | Cold rolling, Cutting, Bending, Stamping, Polishing |

Manufacturing Process

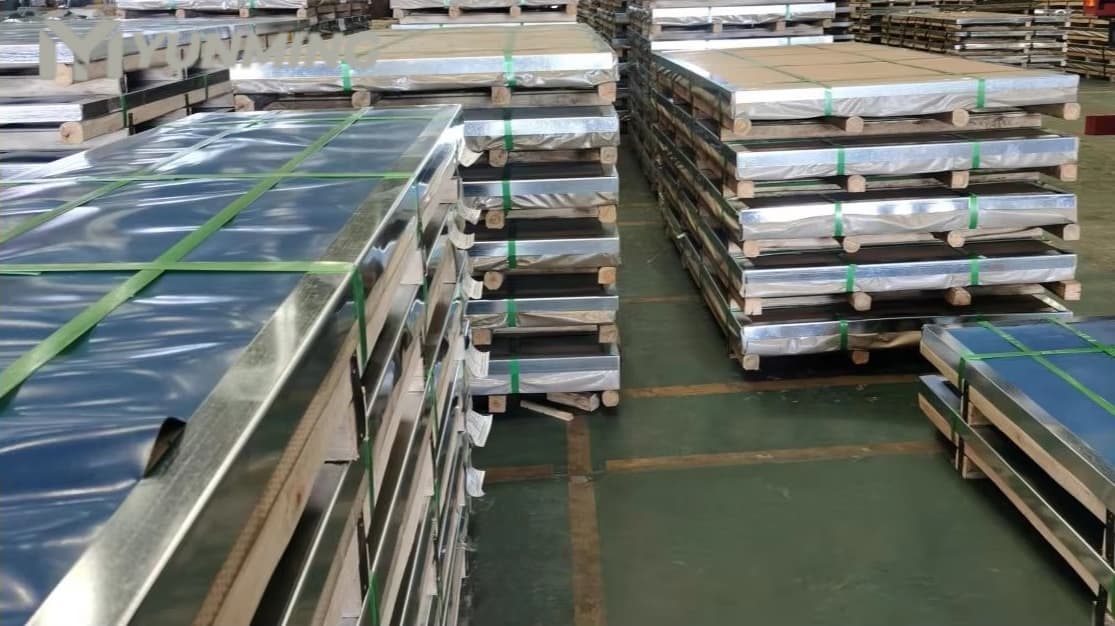

Cold rolled stainless steel sheet and plate are produced by rolling hot-rolled coils below their recrystallization temperature. This process increases material strength and refines the surface quality. After rolling, the material is annealed and pickled, then subjected to further finishing steps such as skin passing or polishing. Every batch undergoes strict dimensional and surface quality inspection to ensure consistency and compliance with international standards.

FAQ

Q: What is the key difference between cold rolled and hot rolled stainless steel?

A: Cold rolled stainless steel has a smoother surface, tighter tolerance, and greater strength compared to hot rolled, making it better for precision applications.

Q: Can I get both sheet and plate in custom sizes?

A: Yes, we offer cold rolled stainless steel sheet and plate in customized thickness, width, and length according to your project needs.

Q: What surface finishes are available?

A: Options include 2B, BA, HL, No.4, 8K mirror, etched, and embossed, suitable for functional and decorative uses.

Q: Are your products suitable for welding and fabrication?

A: Absolutely. Our cold rolled stainless steel products have excellent formability and weldability.

Q: What’s the minimum thickness you can supply?

A: We can supply down to 0.03 mm (1/32″) thickness depending on the material grade and application.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom cold rolled stainless steel sheet and plate requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.