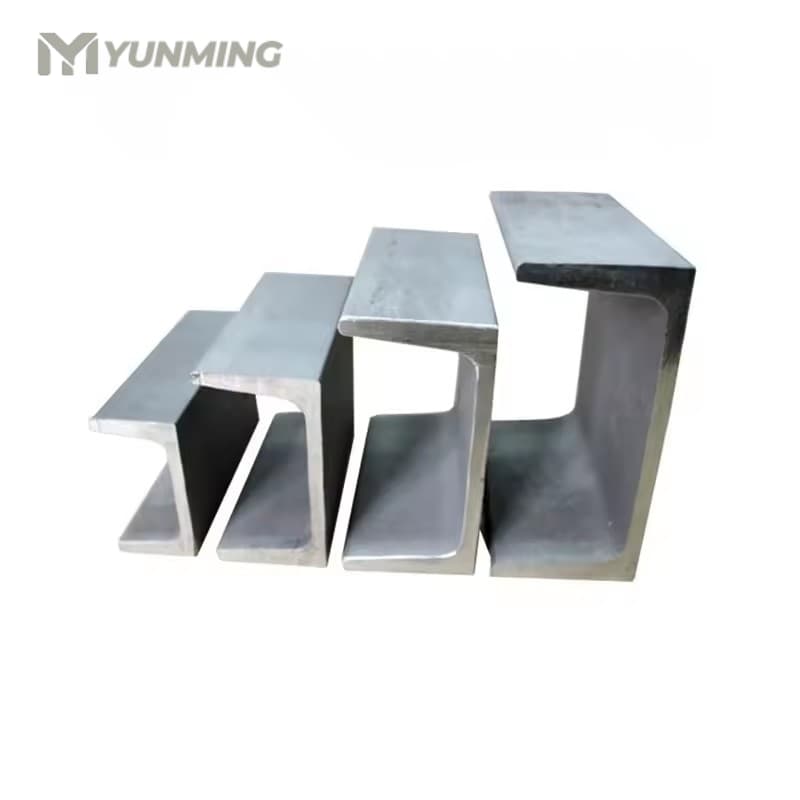

Stainless Steel Channel steel

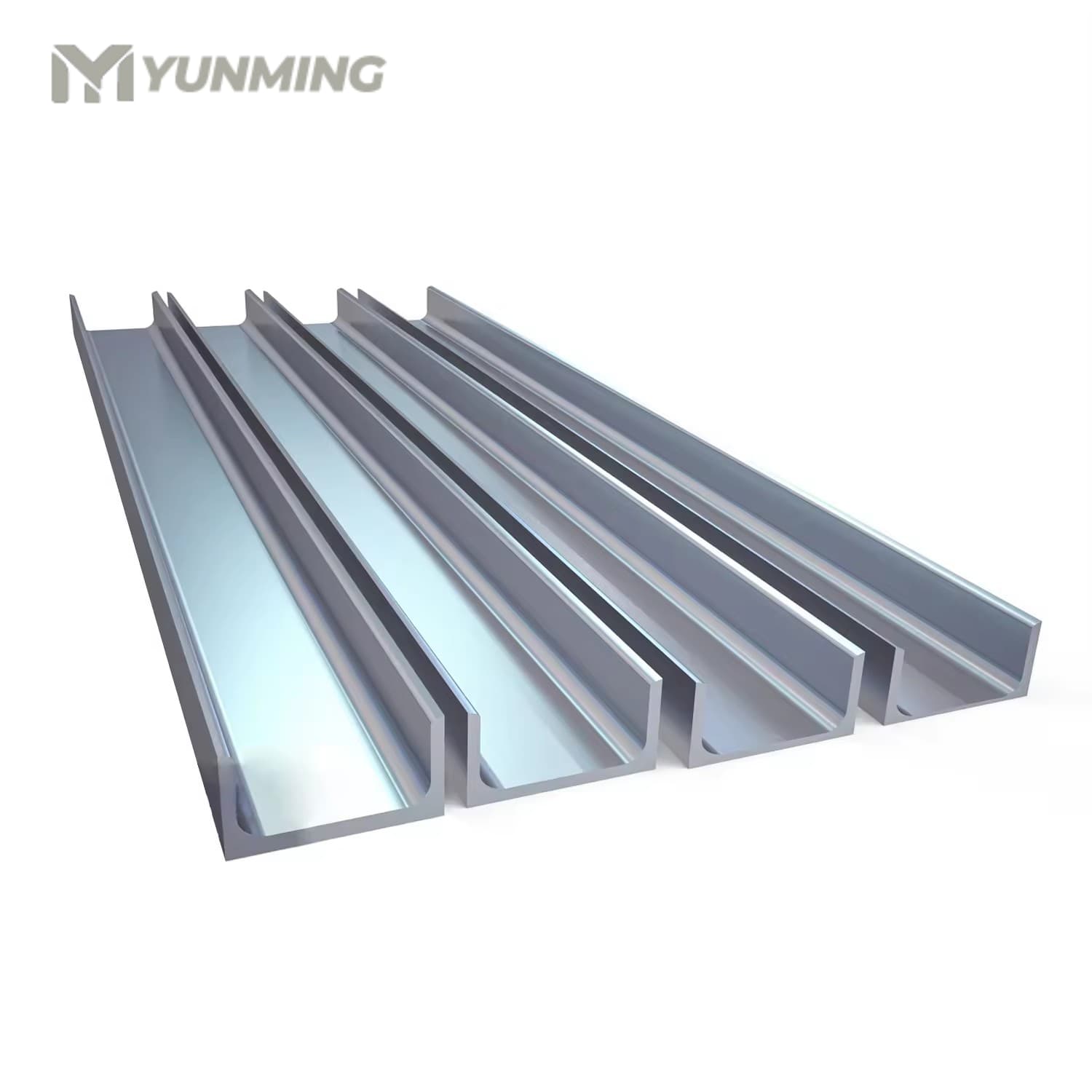

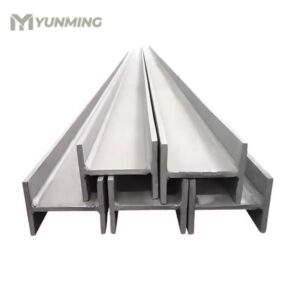

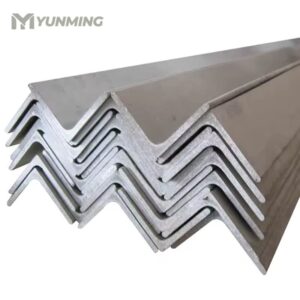

Yunming Metal supplies stainless steel channel steel in U-shaped profiles, offering strength, corrosion resistance, and dimensional accuracy. Available in hot-rolled, welded, and custom-processed formats, suitable for structural framing, machine supports, and industrial applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Stainless steel channel steel is a U-shaped structural profile widely used in industrial and architectural applications. It combines high strength, corrosion resistance, and precise dimensional tolerances, making it ideal for load-bearing components, frameworks, and support systems in demanding environments.

Application Areas

-

Construction & Architecture – Beams, lintels, framing, curtain wall support

-

Equipment Manufacturing – Machine frames, chassis, enclosures

-

Automotive & Transport – Trailer structures, railings, reinforcements

-

Marine & Offshore – Platforms, ladders, handrails

-

Chemical Plants – Corrosive environment support channels

Product Features

-

Excellent corrosion resistance in aggressive environments

-

Uniform U-profile for consistent structural support

-

Available in hot-rolled and laser-welded formats

-

Easy to process: cut, weld, drill, or polish

-

Available in standard and custom sizes for diverse project needs

Technical Specifications

| Specification | Range |

|---|---|

| Height (H) | 30 mm – 300 mm (1 3/16″ – 11 13/16″) |

| Flange Width (B) | 15 mm – 100 mm (9/16″ – 3 15/16″) |

| Web Thickness (t) | 3 mm – 20 mm (1/8″ – 13/16″) |

| Length | Up to 12,000 mm (472″) or customized |

| Steel Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507, 904L |

| Standards | ASTM A276, ASTM A484, JIS G3192, EN 10055, GB/T 706 |

| Surface Finish | Pickled, polished, mill finish, sandblasted |

Manufacturing Process

Stainless steel channel steel is manufactured via hot rolling, cold forming, or laser welding. Hot-rolled channels are shaped from billets, while welded types are fabricated from precision-cut stainless steel plates. All profiles undergo straightening, surface treatment, and dimensional inspection to meet international tolerance and mechanical strength standards.

FAQ

Q: What’s the difference between U channel and C channel?

A: Both are similar in shape, but U channels typically have deeper webs and are preferred for structural support. The terms are often used interchangeably depending on region.

Q: Can you supply custom channel sizes?

A: Yes, we manufacture channels in both standard and custom dimensions, including cut-to-length and punched versions.

Q: Is stainless channel suitable for outdoor use?

A: Absolutely. Grades like 316 and duplex stainless steel offer excellent performance in outdoor and marine conditions.

Q: What surface finishes are available?

A: Options include mill finish, acid pickling, mirror polishing, and custom coating per application.

Q: Do you provide cutting or secondary processing?

A: Yes, we offer laser cutting, drilling, welding bevels, and packaging customization upon request.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom stainless steel channel steel requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.