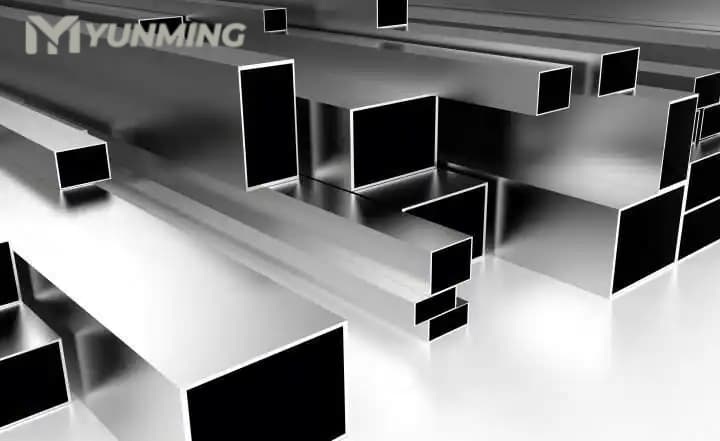

Stainless Steel Flat Tube

Yunming Metal’s Stainless Steel Flat Tubes offer a low-profile rectangular design, excellent corrosion resistance, and smooth surface finishes for structural and decorative applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Stainless steel flat tubes are widely used in structural and decorative applications that require a low-profile rectangular shape. These tubes provide excellent corrosion resistance, smooth surfaces, and precise dimensional tolerance, making them ideal for architectural, mechanical, and industrial designs.

Their flat-sided design ensures strength and uniformity, while also offering a clean, modern aesthetic for interior and exterior use.

Application Areas

-

Architectural handrails and structural frames

-

Furniture design and decorative supports

-

Door and window frames, balustrades

-

Machine brackets and mechanical enclosures

-

Automotive frames and trailer construction

-

General fabrication and engineering projects

Product Features

-

Rectangular flat design suitable for compact structures

-

Excellent resistance to corrosion, rust, and weathering

-

Consistent wall thickness and dimensional accuracy

-

Easy to process: cut, weld, polish, and drill

-

Decorative finishes available for aesthetic appeal

-

Custom sizes and surface treatments offered upon request

Technical Specifications

| Item | Description |

|---|---|

| Material Grades | 304, 304L, 316, 316L, 321, 310S, 317L, 904L, 430, duplex 2205, 2507, etc. |

| Outer Dimensions | 10mm × 10mm – 200mm × 200mm (approx. 3/8″ × 3/8″ – 8″ × 8″) |

| Wall Thickness Range | 0.5mm – 20mm (approx. 1/64″ – 25/32″) |

| Length | Up to 12 meters (approx. 39′ 4″) or customized (cut-to-length available) |

| Surface Finish | 2B, BA, Mirror, Satin, Hairline, Pickled, etc. |

| Manufacturing Standards | ASTM A554, ASTM A269, EN 10219, DIN 2395, GB/T 18705, etc. |

Manufacturing Process

-

Stainless steel coils are slit into required widths

-

Precision roll forming creates the flat rectangular shape

-

High-frequency or TIG welding is used for seam joining

-

Weld seam is polished and optionally heat treated

-

Surface finishes applied: mirror polish, hairline, or satin

-

Tubes are cut to desired length and straightened

-

Final quality control includes visual, dimensional, and weld inspections

Frequently Asked Questions (FAQ)

Q1: What is a flat tube used for?

A1: Flat tubes are ideal for structural, architectural, and decorative applications where a low-profile rectangular shape is needed.

Q2: Do you provide mirror-polished flat tubes?

A2: Yes, mirror, satin, and hairline finishes are available based on your application requirements.

Q3: Can I request a custom width or thickness?

A3: Absolutely. We can customize dimensions and finishes to meet your project specifications.

Q4: Are these tubes suitable for outdoor use?

A4: Yes, especially grades like 304, 316, and duplex stainless steel offer excellent outdoor corrosion resistance.

Q5: What industries commonly use stainless steel flat tubes?

A5: Common industries include construction, furniture, machine building, and decorative metal fabrication.