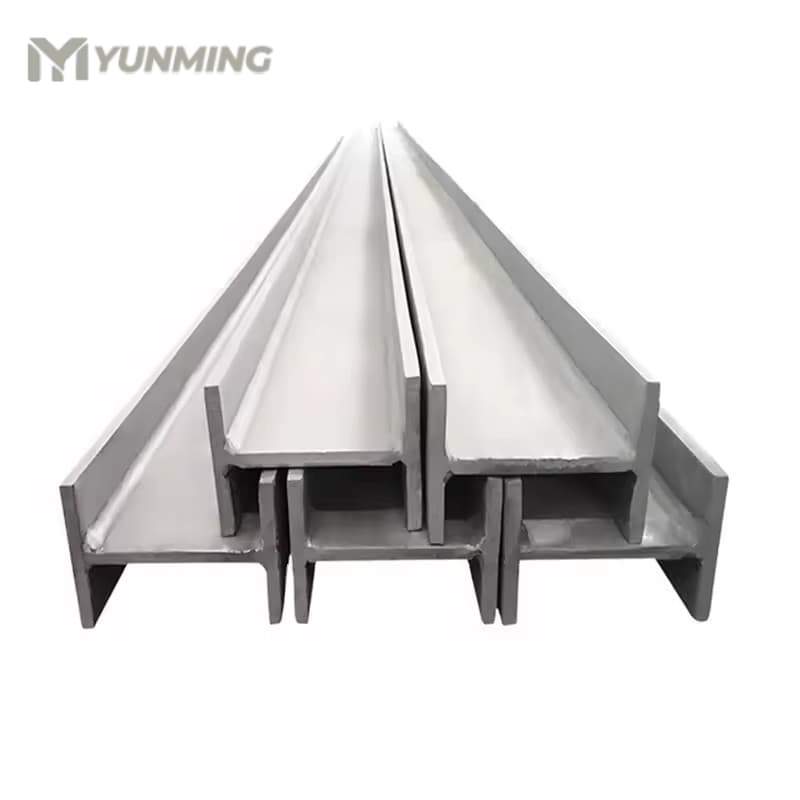

Stainless Steel H Beam

Yunming Metal supplies stainless steel H beams with high load-bearing capacity and corrosion resistance. Available in a wide range of sizes, thicknesses, and grades including 304, 316L, and duplex stainless steel. Ideal for industrial structures, bridges, and offshore applications.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Stainless steel H beams are structural profiles with a wide flange and high load-bearing capacity, designed for applications requiring strength, corrosion resistance, and long service life. With excellent mechanical properties and a precise H-shaped cross-section, they are widely used in industrial construction, structural framing, bridges, and marine environments.

Application Areas

-

Industrial Buildings – Load-bearing columns, roof support frames, steel structures

-

Shipbuilding and Offshore Projects – Platforms, decks, bulkheads

-

Bridges and Infrastructure – Girders, trusses, reinforcement beams

-

Equipment Frames – Machinery foundations, heavy-duty support bases

-

Chemical & Petrochemical Plants – Corrosive environment structural support

Product Features

-

High structural strength with optimal weight-to-load ratio

-

Excellent corrosion resistance in harsh or marine conditions

-

Uniform H-section for easy fabrication and alignment

-

Available in a wide range of sizes and stainless steel grades

-

Weldable, cuttable, and suitable for surface finishing or machining

Technical Specifications

| Specification | Range |

|---|---|

| Height (H) | 100 mm – 900 mm (4″ – 35 7/16″) |

| Flange Width (B) | 50 mm – 300 mm (2″ – 11 13/16″) |

| Web Thickness (t1) | 5 mm – 30 mm (3/16″ – 1 3/16″) |

| Flange Thickness (t2) | 5 mm – 40 mm (3/16″ – 1 9/16″) |

| Length | Up to 12,000 mm (472″) or customized |

| Steel Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507, 904L |

| Standards | ASTM A276, ASTM A484, JIS G3101, EN 10025, GB/T11263 |

| Finish Options | Pickled, polished, sandblasted, or mill finish |

Manufacturing Process

Stainless steel H beams are produced by hot rolling or welding processes. Hot rolled H beams are shaped directly from billet through rolling mills, while welded beams are fabricated by joining cut steel plates. All beams undergo straightening, ultrasonic testing, and surface treatment. Dimensional accuracy and mechanical strength are ensured through rigorous quality inspection in compliance with international standards.

FAQ

Q: What is the difference between H beam and I beam?

A: H beams have wider flanges and thicker web sections, making them stronger and more stable for load-bearing structures.

Q: Can you supply custom sizes?

A: Yes, we offer H beams in customized dimensions, lengths, and surface finishes based on your project requirements.

Q: Are stainless steel H beams suitable for outdoor use?

A: Absolutely. Their corrosion resistance makes them ideal for outdoor and marine environments.

Q: What surface finishes are available?

A: Mill finish, pickled, polished, and sandblasted finishes are available depending on the application.

Q: Do you provide cut-to-length service?

A: Yes, we offer cut-to-length, drilling, and welding preparation services as per customer request.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom stainless steel H beam requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.