Super Duplex Stainless Steel

Yunming Metal provides an overview of Super Duplex Stainless Steel, including grades like S32760 and 2507. Learn about its corrosion resistance, mechanical strength, and applications in oil & gas, marine, and chemical sectors. Contact us for more details.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Super Duplex Stainless Steel is a high-performance alloy known for its excellent combination of mechanical strength and corrosion resistance. It features a mixed microstructure of austenite and ferrite, offering superior resistance to stress corrosion cracking and pitting. Common grades include UNS S32750 and S32760, widely used in harsh environments like offshore platforms and chemical processing.

Application Areas

-

Offshore oil and gas platforms

-

Desalination plants and seawater systems

-

Chemical and petrochemical processing

-

Heat exchangers and pressure vessels

-

Marine and shipbuilding components

-

Pulp and paper manufacturing

-

Flue gas scrubbers and pollution control systems

📎 View Detailed Product Pages

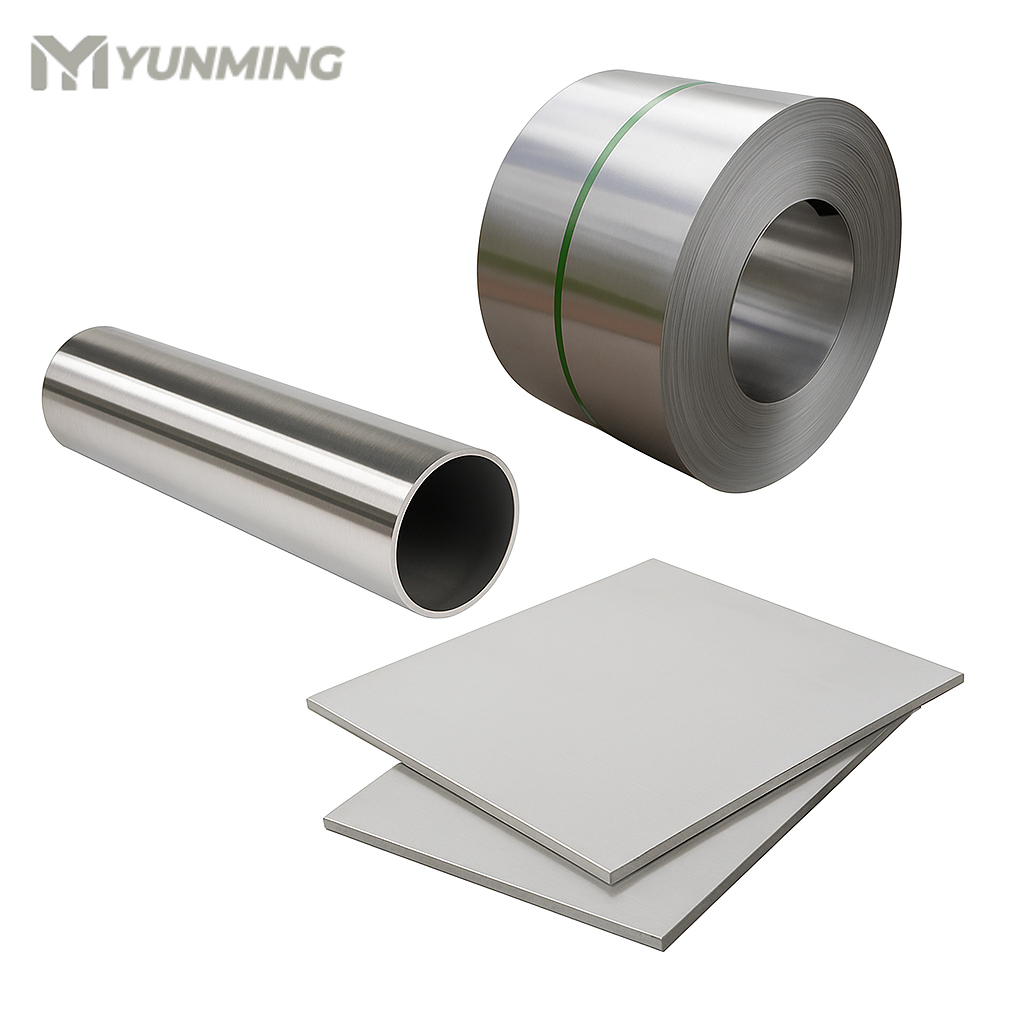

🔹 View Super Duplex Stainless Steel Pipe

🔹 View Super Duplex Stainless Steel Coil

🔹 View Super Duplex Stainless Steel Plate

Product Features

-

Excellent resistance to chloride-induced stress corrosion cracking

-

High tensile and yield strength

-

Greater strength than 300 series stainless steels

-

Superior resistance to pitting and crevice corrosion

-

Suitable for high-pressure and high-temperature applications

-

Available in various forms: pipe, tube, coil, plate, fittings

-

Compliant with ASTM, ASME, EN, and ISO standards

Technical Specifications

| Parameter | Range |

|---|---|

| Grades | UNS S32750, UNS S32760, 2507 |

| Forms | Seamless Pipe, Plate, Coil, Tube, Flanges, Fittings |

| Outer Diameter | ½″ – 24″ (approx. 12.7 mm – 610 mm) |

| Wall Thickness | SCH10S – SCH160 / XXS |

| Standards | ASTM A790 / A789, ASME SA, EN 10216-5, NACE MR0175 |

| Surface Finish | Pickled, Annealed, Polished, Brushed |

Manufacturing Process

-

Raw material inspection and alloy verification

-

Melting and refining in EAF or AOD furnaces

-

Hot rolling or cold drawing

-

Solution annealing and quenching

-

Surface pickling or mechanical finishing

-

Dimensional inspection and NDT

-

Marking, packaging, and delivery

Frequently Asked Questions (FAQ)

Q1: What is the difference between Duplex and Super Duplex?

A1: Super Duplex contains higher levels of chromium and molybdenum, providing better corrosion resistance and strength.

Q2: Can Super Duplex withstand seawater exposure?

A2: Yes, it is highly resistant to seawater corrosion, especially in chloride-rich environments.

Q3: What certifications are available?

A3: We provide EN10204 3.1 / 3.2 certificates, NACE MR0175 compliance, and ISO 9001.

Q4: Is custom machining available for Super Duplex materials?

A4: Yes, we offer cutting, beveling, polishing, and customized fabrication on request.

Q5: What is the minimum order quantity (MOQ)?

A5: Flexible MOQ for first-time orders. Contact us to discuss specific requirements.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom Super Duplex stainless steel requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.