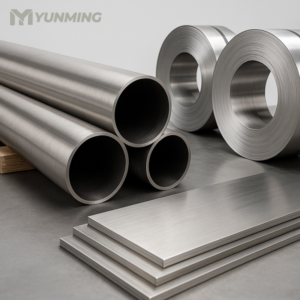

Super Duplex Stainless Steel Pipe

Super Duplex Stainless Steel Pipe provides outstanding strength and resistance to chloride corrosion. Ideal for offshore, petrochemical, and desalination systems. Available in seamless and welded types, in a wide range of diameters and wall thicknesses.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Super duplex stainless steel pipes are engineered for highly corrosive and high-pressure environments. With a dual-phase microstructure of austenite and ferrite, they offer superior strength and outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking. These pipes are ideal for demanding applications such as offshore oil platforms, desalination systems, and chemical processing lines.

Application Areas

-

Offshore oil & gas platforms

-

Chemical and petrochemical plants

-

Desalination and seawater systems

-

Pulp and paper processing lines

-

Power generation and heat exchangers

-

Structural components in marine environments

Product Features

-

Excellent resistance to chloride-induced corrosion

-

High yield and tensile strength

-

Dual-phase structure: ferritic-austenitic

-

Suitable for welding, bending, and machining

-

Low thermal expansion and high fatigue strength

-

Fully compliant with ASTM, ASME, EN, and NORSOK standards

Technical Specifications

| Parameter | Range |

|---|---|

| Outside Diameter | 12.7 mm – 610 mm (approx. ½″ – 24″) |

| Wall Thickness | SCH10S – SCH160 / XXS |

| Length | Up to 12,000 mm (customized available) |

| Material Grades | UNS S32750 / S32760 / S39274 |

| Manufacturing Method | Seamless or Welded |

| Surface Finish | Pickled, Polished, Sandblasted |

| End Types | Plain End, Beveled End, Threaded End |

| Standards | ASTM A790 / ASME SA790 / EN 10216-5 |

Manufacturing Process

-

Material cutting and preparation

-

Hot forming or cold drawing

-

Heat treatment (solution annealing)

-

Pickling or mechanical finishing

-

Ultrasonic & hydrostatic testing

-

Marking, packaging, and export inspection

FAQ

Q1: What is the main advantage of super duplex pipes over 316L stainless steel?

A1: Super duplex pipes offer nearly twice the strength and significantly better resistance to pitting and crevice corrosion than 316L.

Q2: Are these pipes suitable for seawater desalination?

A2: Yes. Their superior corrosion resistance makes them ideal for use in desalination systems.

Q3: Do you provide MTCs and third-party inspections?

A3: Yes. All shipments come with EN 10204 3.1 certificates, and third-party inspections (BV, SGS, TUV) are available upon request.

Q4: Can these pipes be customized in non-standard dimensions?

A4: Yes. We offer custom fabrication services based on project-specific drawings or technical specifications.

Q5: What welding methods are suitable for super duplex pipes?

A5: TIG and MIG welding with proper filler metal and heat input control are recommended for maintaining corrosion resistance.

Still Have Questions?

Feel free to contact us for more details or to discuss your super duplex piping requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.