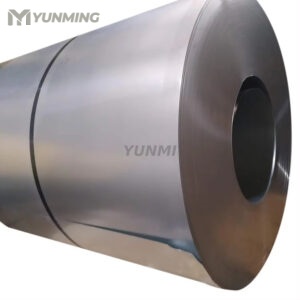

Hot Rolled Stainless Steel Coil

Yunming Metal offers hot rolled stainless steel coils in 304, 316L, 310S, and duplex grades. Ideal for pressure vessels, construction, and heavy-duty fabrication. Available in custom widths, finishes, and processing options.

Have questions? YUNMING sales representatives are available for live chat now

Product Overview

Hot rolled stainless steel coil is produced by heating stainless steel slabs above recrystallization temperature and rolling them into coil form. It offers excellent weldability, corrosion resistance, and high-temperature strength, making it suitable for structural, industrial, and high-load applications.

Application Areas

-

Pressure vessels and heat exchangers

-

Petrochemical and power generation equipment

-

Construction beams, frames, and columns

-

Shipbuilding and marine applications

-

Industrial tanks, pipelines, and railway cars

-

Heavy-duty automotive components

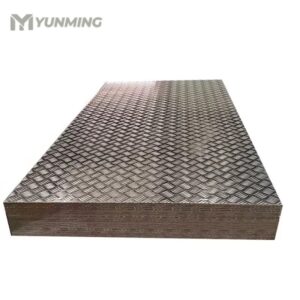

Product Features

-

High strength and load-bearing capacity

-

Good formability and weldability

-

Excellent resistance to oxidation and scaling at elevated temperatures

-

Available in a wide thickness range

-

Suitable for further processing: cutting, decoiling, bending, punching

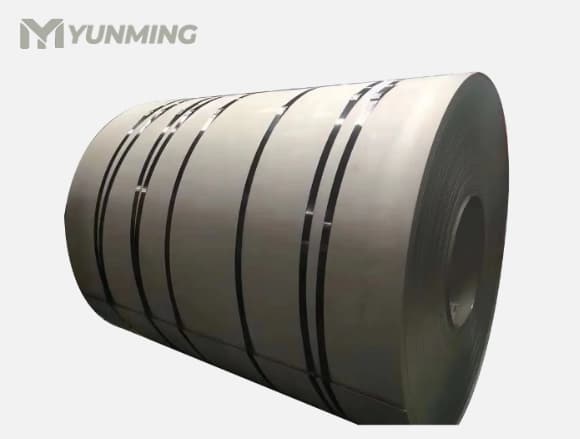

Technical Specifications

| Specification | Range |

|---|---|

| Material Grades | 304, 304L, 309S, 310, 310S, 316, 316L, 316Ti, 321, 430, 410, 420, 2205, 904L |

| Standard Thickness | 3 mm – 16 mm (approx. ¹⁄₈″ – ⁵⁄₈″), customizable |

| Standard Width | 1000 mm – 2000 mm (approx. 39″ – 79″), can be customized up to 2500 mm |

| Coil ID / OD | ID: 508 mm or 610 mm (approx. 20″ or 24″), OD: up to 2000 mm (≈ 79″) |

| Finish Options | No.1, black annealed, shot-blasted, pickled |

| Standards | ASTM, AISI, JIS, EN, DIN, GB, SUS |

| Processing Services | Cutting, welding, decoiling, bending, punching, slitting |

Manufacturing Process

Hot rolled stainless steel coil is manufactured by heating billets or slabs to a temperature above 1100°C (2012°F) and passing them through rolling mills to reduce thickness. The coil is then annealed and pickled to remove scale, improving surface quality and corrosion resistance. Final coils are edge-trimmed and prepared for custom processing.

FAQ

Q: What is the difference between hot rolled and cold rolled stainless steel coils?

A: Hot rolled coils are thicker, less precise in finish, and better suited for structural applications, while cold rolled coils have tighter tolerances and a smoother surface.

Q: Can I request customized thickness and width?

A: Yes, we support custom dimensions according to project requirements, including thickness up to 16 mm and width up to 2500 mm.

Q: Which surface finish is standard for hot rolled coils?

A: No.1 finish (annealed and pickled) is standard, but black and shot-blasted finishes are also available.

Q: Are hot rolled coils suitable for pressure vessels?

A: Yes, especially in grades like 316L or 310S, hot rolled coils are used in high-pressure and high-temperature vessels.

Q: What grades are available for marine or salt-exposed environments?

A: For such environments, we recommend 316L or duplex stainless steel like 2205 for superior corrosion resistance.

Still Have Questions?

Feel free to contact us for more details or to discuss your custom hot rolled stainless steel coil requirements. Our technical support team is ready to assist with specifications, certifications, and delivery.